高耐蚀铝制空调换热器表面防腐工艺

JSK-TDS-362

Version No.: 2020-09-30

高耐蚀铝制空调换热器表面防腐处理工艺

surface anti-corrosion treatment process of heat exchanger

1. 概述:

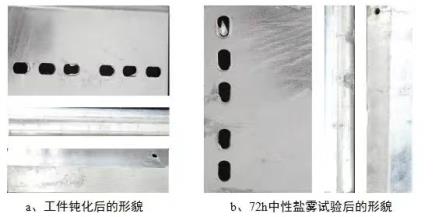

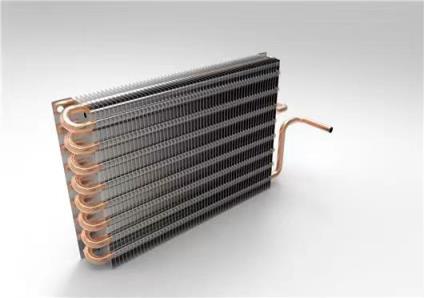

空调铝制换热器 主要材料是3系铝以及部份纯度在99%以上的紫铜, 二者通过铅焊工艺结合固定成型;其表面防腐处理的难点重点在于铅焊结合部、在于铝铜二者兼顾,经过防腐处理后 让整体均能保证过中性盐雾72小时(相当于户外气候环境下8年)。

目前业界应对工艺有喷粉烤漆、 钝化封闭等;从综合效能上考率, 我们佳士克推荐钝化封闭工艺;

2. 工艺细述:

脱脂----洗水---抛光-- 钝化---洗水---洗水----封闭液浸泡1分钟-----洗水----烤干----喷封闭液----洗水----烤干

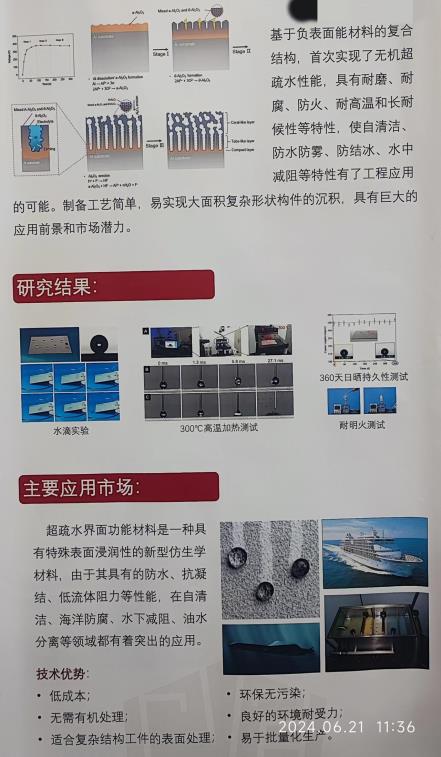

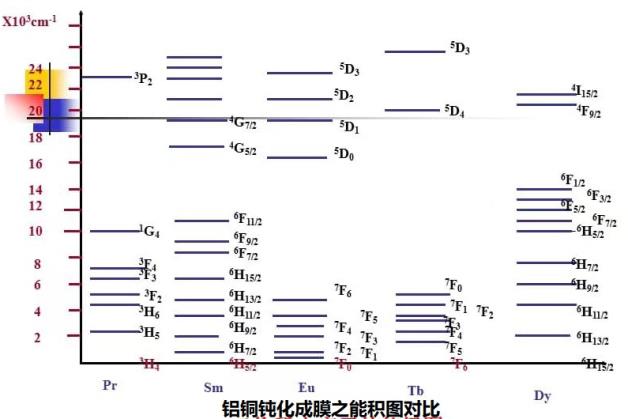

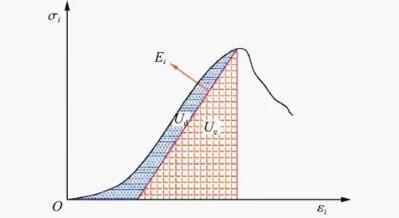

防腐原理图示:

3. 使用佳士克该工艺之产品表面除得到优良耐蚀性外, 其优良的耐磨、导热、超疏水、超滑水性能亦是可圈可点:

使用该钝化工艺,相较于传统的打磨----除油----喷粉---烤漆 工艺, 综合成本下降30%

Corrosion resistance of anodized aluminum sealed with conventional and a new

sealant was tested against the alkaline,acid and neutral chloride salt solutions.The results show

that solution based the conventional nickel salt have good acid and neutral salt fog

resistance,however,they do not possess the necessary alkaline corrosion resistance to be used for

decorative and automotive exterior applications.The author develops a new alkaline

corrosion-resistant sealant and relative process which has passed the standard test made by

automotive industry.Results revealed that this new sealant and process has excellent alkaline

corrosion-resistant property ,be significantly capable of meeting requirement of the automotive